| |

|

|

|

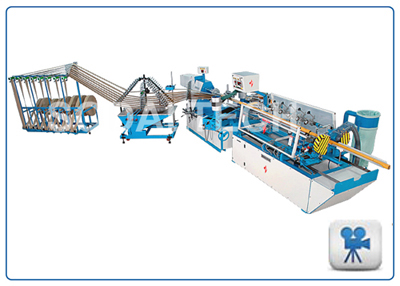

Paper Tube and Core Production Line |

|

SALIENT FEATURES

- Higher

output

- Extra strong tubes

- Electronic proportional control system

for winding

- speed adjustment

- Rapidly interchangeable mandrels

- Pneumatic control of winding belt tension

- Built-in control panel with remote station.

|

|

|

|

| |

|

Paper Tube Winder with Multi Cutter for Kitchen Foil Tubes

This versatile spiral Paper Tube Winder is to deliver high output of pre-cut cores for toilet tissue winding, kitchen foil winding etc.

|

|

Fully Automatic Textile Tube Making Machine

with Automatic Recutter and Finishing Machine

SALIENT FEATURES

- Easy to operate and maintain

- Easy interchangeability of toolings

- Highly suitable for DTY Tubes production

|

| |

|

|

|

|

|

| |

|

Paper Tube Winder - cCW MODEL

This machine is used to manufacture thin, medium walled paper tubes and cores for tissue rolls, fax rolls etc.

SALIENT FEATURES

- Output : Up to 15 mts/min. depending upon the sizes of the tube

- Minimum inner diameter : 25 mm

- Maximum inner diameter : 100 mm

- Maximum wall thickness : 5 mm

|

|

|

|

| |

|

| Paper Core Winder

This heavy duty Spiral Paper Core winder is suitable to produce thick walled cores for various applications like paper mill reel cores, film winding cores, carpet cores etc.

This machine is easy to operate and maintain. The cutting carriage moves on free slide rails synchronized with the main tube winder. The online fine cutting unit delivers burr free cores without dust and noise generation.

SALIENT FEATURES

- Output : Up to 15 mts/min. depending upon the sizes of the tube

- Minimum inner diameter : 30 mm

- Maximum inner diameter : 500 mm

- Maximum wall thickness : 16 mm

|

|

|

|

|

|

Automatic

Tube Finishing Machine

This automatic Tube Finishing Machine is suitable for finishing textile yarn carriers like DTY and POY tubes and fitted with automatic tube transfer mechanism.

SALIENT FEATURES

Machine capable of doing following operations :

- Both ends polishing

- One end curling & other end polishing

- Easy interchangeability of toolings

- Thread notch depth angles & reference

are easily adjustable

|

|

|

|

|

|

Heavy Duty Slitter Rewinder ETS 2000

SALIENT FEATURES

- Maximum parent reel width (approx) : 2000mm

- Parent reel outer diameter (approx) : 1300mm

- Slit reel outer diameter (maximum) approx : 1300mm

- Minimum slitting width : 75mm

- Maximum cutting stations : 27 Nos

- Output Speed (approx) : 100 metres per minute depending on the quality of the raw material, size etc

- Parent Paper Reel Loading : Automatic

- Parent Paper Reel Clamping : Automatic

- Unloading of slit reel : Automatic

- Maximum weight of the parent reel (approx) 800 Kgs

- GSM Range : 100 GSM to 600 GSM

- Paper Core Size : 3” Both Unwind and Rewind station

- Total Power (approx) : 13 KW

- Air Supply requirement : 6 Bar (100 lpm)

- Trim waste removal system

- Shaftless paper reel clamping

- Numerical braking system for tension control

|

|

|

|

|

|

|